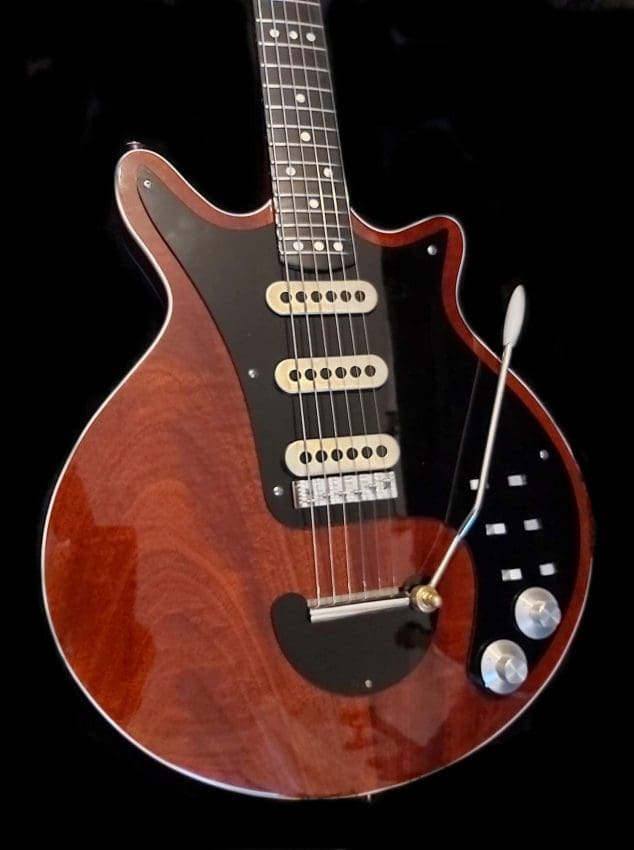

This time on Meet the Maker I got to ask Loxley Custom Guitars’ Matthew Loxley what got him into making guitars and how he approaches the art of guitar building. The Sheffield, England-based luthier has a huge following and specializes in making some pretty unique guitars, including their take on the Moderne and a certain very well-known Special.

What got you into building instruments?

Many years ago my dad brought an old electric guitar body back from work he had found forgotten in a corner. It was a nice sunburst color, a Tele/Strat hybrid kind of thing. We spent a fair amount of time finding a neck for it, electronics, and parts. Neither of us knew much about guitars at that point (even though there were always a few in the house) so we did the best we could. It played and sounded pretty good (I still have it somewhere!) and I was bitten by the bug.

As many people do, I started putting guitars together from parts, but being artistic, I fancied building them from scratch. My first full build was a set neck, spalted beech-topped SG with inlays. In for a penny, in for a pound! I designed my headstock and body shape around a decade ago, the Cygnus, which I’m finally getting around to building, and will have a number finished this year.

Who/What are your biggest influences with instrument building?

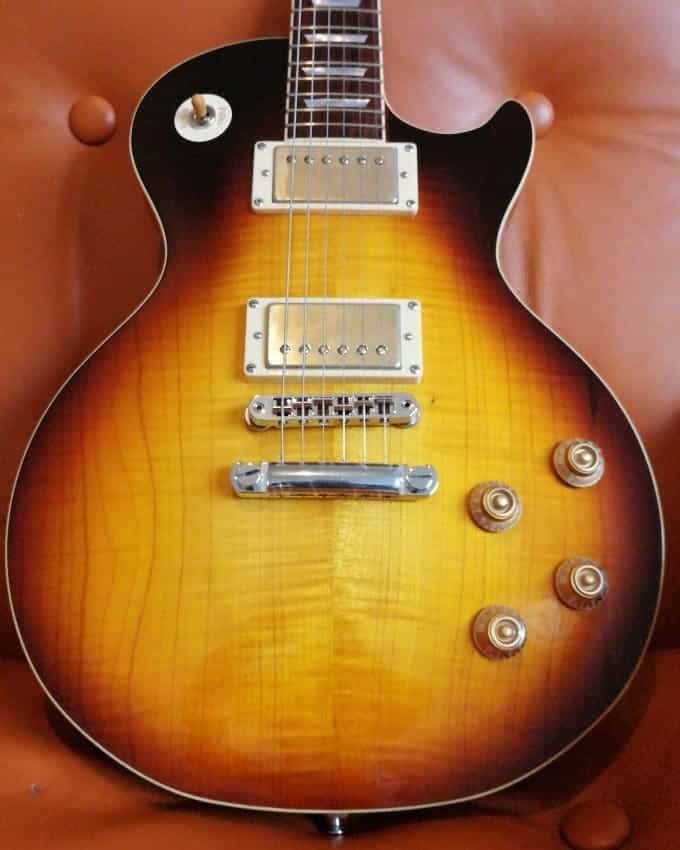

Being a big G&R/Slash fan I’ve always had an interest and appreciation for Gibson and the Les Paul, for something that’s 70 years old, the shape, form, layout, and scale are timeless. The history of guitars is also fascinating to me, the changes, advancements, and processes that were made over such a short timeframe in the 50s are incredible really.

The innovation and craftsmanship of these early instruments interest me, and as a small builder, I feel some affiliation with what they were doing back then.

Moving forward Paul Reed Smith has been another big influence. Looking at existing guitars, stripping them back, and seeing what can be improved. Such as using a dovetail set neck instead of a mortice and tenon, faux binding to show off the figured maple caps, the iconic scoop in the top to aid upper access, and the use of a varied array of beautiful woods you didn’t see in production instruments before this point.

I feel it’s important as a builder to understand why other guitar makers have made certain changes and potentially incorporate those improvements into your guitars.

What is your favorite part of the process of instrument making?

Carving the neck for sure. This is where the instrument is really made special. I will always spend a fair amount of time with customers discussing exactly how they want the guitar and neck to feel. A lot of my work is bespoke twists on guitars people like with their own touches, and neck shape is one of the biggest factors.

It’s also very therapeutic, gently turning a rectangle of wood into a comfortable, ergonomic neck that people want to hold and play. Getting them just right is very rewarding.

How should potential new clients get prepared when buying a new instrument from you?

Do a lot of research. Having a custom instrument made is all about the fine details. It’s helpful to know from the outset what a customer wants. Body shape, scale length, neck shape, what timbers they would like, and how they want it to sound. I’m lucky that I know some talented people who can make brilliant custom pickups and hardware that’ll set the guitar apart.

I enjoy talking through options with customers and coming up with the foundations of a really special instrument.

How would you describe your style of instrument building?

Organic and ever-evolving. 99% of my instruments are handcrafted. Using templates, routers, chisels, spokeshaves, and Japanese saws. A lot of time and attention is given to creating unique guitars, that both look and sound incredible. I’ve built a bit of a reputation for making guitars others wouldn’t. I rarely make two guitars the same, this keeps things interesting and means when someone gets a Loxley guitar they know it’s the only one.

I enjoy experimenting with timbers and often build guitars with multi-laminated heels, scarf joints, and bodies. These not only make the guitars stronger but also make them stand out.

I also make a real point of customer interaction. I frequently update customers with progress and many photos of their guitar build, from the choice of the timbers, the process of the building of the instrument, and the assembly. This has proved a real hit with customers as they feel they are along for the ride!

What’s the biggest mistake you’ve made while learning your craft?

In the early days, it was an excess of youthful exuberance and a lack of patience. Rushing to get things done when there was no need. As there are so, so many processes in building a guitar, it takes a lot of time and practice to learn how to do them all well.

As a small business building guitars, we have to be able to do the woodwork, electronics, fretwork, setup, finishing work, and assembly. Building a really special instrument can’t be rushed and this is what makes them stand out against the competition.

Why should musicians buy a luthier-made instrument?

Choice!

Some people are happy to pick another generic instrument off the shelf and use that, but I know a lot of guitarists who have played for years and know exactly what they want. There’s a big push it seems now in customs shops where the cost is pushed up exponentially for something a little different to the standard.

Luthiers generally do this as a point of course. We have real pride in our instruments and due to the time and effort invested want our instruments to be the best they can be. I think this is where the real difference is, you’re purchasing someone’s skills, expertise, and pride as well as an instrument. Customers can generally specify things that aren’t available on stock instruments. A specific neck wood, an inlay that means something to them, or pickups voiced to their requirements.

Do you have a personal favorite style of instrument?

A vintage Les Paul! Big deep-dish carve, fat 50s neck, Brazilian Rosewood fretboard, and beautiful lightweight mahogany body. I love the shorter scale length and the way the instruments feel and resonate. The dream is to get one one day, for research purposes of course!

What do you feel when you have to hand the new guitar/bass over to its new owner? and Do you ever want to keep them instead?

It’s unlike anything else really; a mixture of nervousness, excitement, and pride. There are countless hours of hard work and concentration put into each instrument and you hope you have got the guitar just right for the customer. The look on someone’s face, when they open the case for the first time (even after seeing a lot of images), is priceless. To hear it played properly too is always a wonderful moment, knowing you made the guitar is a real sense of pride.

In the early days, it was a lot more difficult to let them go, but after building 60+ guitars it gets easier. There have been a few that I have personally really liked the feel and tone of that I’d be happy to not let go, but I think that just means I’m doing something right.

What do you want your legacy to be?

When I started out making guitars properly, the legacy was something that appealed to me. Making something that will hopefully outlast me and give both the player and audience countless hours of enjoyment is a really strong incentive. The hope is to build a reputation for creating really special instruments that are well-regarded and sought out. The aim is to have Loxley guitars on big stages worldwide and being used for recordings.

I now have guitars all over the world, which is incredible looking back 10 years when I was just starting. I still have the same enthusiasm and get the same enjoyment from building now as I did then.